|

Making Sense of

Motor Oil

Thin oil flows better than thick oil. It is more effective at cooling. It provides a reduction in friction. You should maintain 10 psi per 1,000 rpm for adequate lubrication. More oil pressure is not better lubrication. Better oil flow is better lubrication.

Not everyone believes that thinner oil is always the right answer. Using a thinner oil is unlikely to give you significantly better fuel economy. You may experience more unwanted noises using a thinner oil. Oil leaks are more likely with thin oil. Some believe that thicker oil helps to reduce oil consumption.

Dr. Ali E. Haas (AEHaas) has written an excellent article entitled Motor Oil Basics.

The information presented here is drawn from that article.

Part I

Motor oil is a confusing subject, with a lot of misconceptions. Sometimes it seems like everyone, including experienced mechanics, feel they are experts in this field but few really understand engine oils. It is easy to see how people get confused as there is always some truth in the misconceptions.

Thickness has the same meaning as viscosity. Viscosity is a measure of the resistance of a fluid (liquid or gas) to flow. Fluids with high viscosity, such as molasses, flow more slowly than those with low viscosity, such as water.

Much of the confusion about motor oils comes about because of the way they are labeled. It is an old system, confusing to many people. I know the person is confused when they say that a 0W-30 oil is too thin for their engine because the owner's manual says to use 10W-30. This is a good example of misconception. At normal operating temperature both oils have the same viscosity. It is only when the oils are at less than normal operating temperature that differences exist.

More confusion occurs because people think in terms of the oil thinning when it gets hot. They think this thinning with heat is the problem with motor oil. It would be more correct to think that oil thickens when it cools to room temperature and THIS is the problem. In fact this is the problem. It is said that 90 percent of engine wear occurs at startup. If we are interested in engine longevity then we should concentrate our attention at reducing engine wear at startup.

Oils are chosen by the manufacturer to give the right thickness at the normal operating temperature of the engine. For the purpose of our discussion we will say this average normal operating temperature of oil is 212 F, the boiling point of water.

One thing that is no longer important for most of us is the ambient temperature. Older automotive owner manuals often recommended one oil for the summer and another for the winter. This is still necessary for air cooled engines but is no longer a primary consideration in pressurized water cooled engines. These engine blocks are kept at around 212 F all year round. The oil is around the same temperature as well. This allows for a single grade oil all year round.

Please forget those numbers on the oil can. They really should be letters as AW-M, BW-N or CW-P. The fact that we are dealing with a system of numbers on the can makes people think that they represent the viscosity of the oil inside the can. The problem is that the viscosity of oil varies with its temperature. A “30” grade oil has a viscosity of 3 at 302 F and thickens to 10 at 212 F. It further thickens to a viscosity of 100 at 104 F and is too thick to measure at the freezing point of 32 F.

Oils are divided into grades (not weights) such as a 20, 30 or 40 grade oils. This represents the viscosity range at operating temperature. But it is NOT the actual viscosity as we shall see. The issue is that viscosity is temperature dependent. Let’s look at a 30 grade oil and how the viscosity of this grade of oil varies with temperature:

30 grade oil (often referred to as a 30 “weight” oil):

Temperature ( F )....Thickness

302...........................3

212..........................10

104..........................100

32............................250 (rough estimate)

The automotive designers usually call for their engines to run at 212 F oil and water temperature with an oil thickness of 10. This is the viscosity of the oil, not the weight or grade as labeled on the oil can. I want to stay away from those numbers as they are confusing. We are talking about oil thickness, not oil can labeling. We are only discussing the thickness of the oil that the engine requires during normal operating conditions.

The best thing for your engine would be that it was never turned off, you simply kept driving day and night. The oil thickness would be uniform, it would always be 10. In a perfect world the oil thickness would be 10 at all times and all temperatures.

The night before when you drove home from work the car was up to the correct

operating temperature and the oil was the correct thickness, 10. Over night the

engine cooled to ambient temperature and the oil thickened. It is

too thick, as we shall see, to lubricate an engine designed to run with an oil having a thickness

of 10.

It is time to introduce the concept of lubrication. Most believe that pressure =

lubrication. This isn't correct. Flow = lubrication. If pressure was the thing that

somehow lubricated your engine then we would all be using 90 grade oil.

Lubrication is used to separate moving parts, to keep them from touching. There

is a one to one relationship between flow and separation. If you double the flow

you will double the separation pressure in a bearing. The pressure at the

bearing entrance is irrelevant.

In fact the relationship between pressure and flow is in opposition. If you change your oil to a thicker formula the pressure will go up. It goes up because the resistance to flow is greater and in fact the flow must go down in order for the pressure to go up. They are inversely related. Conversely if you choose a thinner oil then the pressure will go down. This can only occur if the flow has increased.

It seems then that we should all be using the thinnest oil money can buy. This

is partly true. The gold standard is that all engines should have a pressure

of 10 PSI for every 1,000 RPM of operation, not more, not less. After all, you

do need some pressure to move that oil along, but only enough pressure, not

more. More pressure is not better, it can only result from the impedance of oil

flow. Remember that oil flow is the only thing that does the lubricating.

The oil thickness needed for each application can only be

determined by experimentation. Dr Haas found that in one of his Ferrari's the engine oil temperature was running about 185

F around town. Even when using the thinnest Mobil 1 oil available at the time his oil pressure was 80 PSI at 2,000 RPM. Too thick to provide the ideal pressure for his application.

High flow does more than lubricate. It is one of the things used to cool the hottest parts of your engine, the pistons, valve areas and bearings. This cooling effect is as important as lubrication in your engine. If your engine is running hot you may need to use a thinner oil. The flow will increase and so will the cooling.

It is time to dispel the notion that 0W-30 oil is too thin when your manual calls for 10W-30. A 0W-30 is always the better choice, always. The 0W-30 is not thinner. It is the same thickness as the 10W-30 at operating temperatures. The difference is when you turn your engine off for the night. They both had a thickness, a viscosity of 10 when you got home and turned your engine off. That was the perfect thickness for engine operation.

As cooling occurs and you wake up ready to go back to work the next day the oils

have gotten too thick for your engine to lubricate properly. Your engine wants the oil to have a thickness of 10

to work properly. Multi-viscosity oils were originally developed to help alleviate this thickening problem. Prior to the availability of multi-viscosity oils you might use a 20W in the summer and a 10W in the winter to compensate for ambient temperature differences.

Part II

Most engine wear occurs at startup when the oil is too thick to

lubricate properly. It cannot flow and therefore cannot lubricate. Most of the

thick oil at startup actually goes through the bypass valve back to the engine

oil sump and not into your engine oil ways. This is especially true when you

really step on that gas pedal. You really need more lubrication and you actually

get less.

Even a straight 10 grade oil is also too thick for your engine at startup. It has a thickness of 30. Yet at operating temperatures it is too thin having a thickness of 6. It needs to be around 10. The oil companies have added viscosity index improvers or VII to oils to solve this dilemma. They take a mineral based oil and add VI improvers so that it does not thin as much when it gets hotter. Now instead of only having a thickness of 6 when hot it has a thickness of 10, just as we need.

The penalty is that the startup thickness goes up to 100. This is better than

being up at 250 as a straight 30 grade oil though. Oil with a startup thickness

of 100 that becomes the appropriate thickness of 10 when fully warmed up is

called a 10W-30 grade motor oil. This is NOT as thick as a straight 30 grade oil

at startup and it is NOT as thin as a straight 10 grade oil at full operating

temperature.

The downside of a mineral based multi-grade oil is that this VII additive wears out over time and you end up with the original straight 10 grade oil. It will go back to being too thin when hot. It will have a thickness of 6 instead of 10. If the VII wears out the 0W-30 will ultimately be thinner, a straight 0 grade oil. When the VII is used up in the 10W-30 oil it too is thinner. It goes back to a straight 10 grade oil. They are both still too thick at startup, both of them. The straight 0 grade oil, a 5 grade oil and a 10 grade oil are all too thick at startup.

This is just theory however. With normal oil change intervals the VI improver

will not wear out and so the problem does not really exist. In fact, oils do

thin a little with use. This is partly from dilution with blow-by gasoline and

partly from VI improvers being used up. What is more interesting is that with

further use motor oils actually thicken and this is much worse than the minimal

thinning that may have occurred earlier.

Synthetic oils are a whole different story. There is no VI improver added so there is nothing to wear out. The actual oil molecules never wear out. You could almost use the same oil forever. The problem is that there are other additives and they do get used up. I suppose if there was a good way to keep oil clean you could just add a can of additives every 6 months and just change the filter, never changing the oil.

When the additives wear out in a synthetic oil it still has the same viscosity.

It will not thin as a mineral oil. These oils

will always have the correct thickness when hot and will still be too thick at

startup as with all oils of all types, regardless of the API / SAE viscosity

rating.

Automotive engine manufacturers know these principals of motor oils. They know

there is thinning or thickening that will occur. They take these things into

account when they write that owners manual. Mineral oil change recommendations

will generally include shorter time intervals than those of synthetic

oils.

The reality is that motor oils do not need to be changed because they thin with

use. It is the eventual thickening that limits the time you may keep oil in your

engine. The limit is both time itself (with no motor use) and/or mileage use.

The storage of motor oil in your garage, particularly mineral based oils, slowly

ages the oil limiting its use later. Do not store huge volumes of oil in your

garage that is exposed to extremes of temperature.

Part III

A main advantage a synthetic oil has over a mineral based oil is the

ability to lubricate at startup. Both types of oil have the same specifications

at 104 F, 212 F and 302 F. It is the startup viscosity characteristics that

separate these oils. Synthetic oils do not thicken as much on cooling. They have

better fluidity as the temperature drops.

A synthetic oil that is labeled as 10W-30 is less honey like as a mineral based

10W-30 motor oil at startup. They both have a thickness of 10 at normal

operating temperatures. At 75 F the synthetic is not as thick. At 32 F the

difference between the two is even greater. At 0 F the mineral oil is useless

yet the synthetic works fairly well. Just keep the RPM to a minimum.

At temperatures below zero you will not be able to start your car with mineral

oils while the synthetic oils may be used to -40 or - 50 F. Oils are so thick

that the normal method of viscosity measurement is not possible. Instead we

measure if the oil can even be pumped or poured. Again, we are only discussing a

single category of oil, the multi-grade 10W-30 API / SAE grade.

The synthetic 10W-30 grade oil is based on a heavier 30 grade oil while the

mineral based 10W-30 oil is based on a thinner 10 grade oil. They are both

similar at operating temperatures yet the 30 grade based synthetic is actually

less thick at startup and much less honey - like at low temperatures.

Part IV

Dr. Haas believes that oil is much better being too thin than too thick. In recent years manufactures have been specifying thinner and thinner oils despite hotter engines with

turbos and the like. The tendency is that people figure they need a 40 grade

oils but then use a 50 instead. Better thinking is that if you think you need a

40, use a 30 grade oil instead.

The thickness of moving oil is measured in centiStokes or cS. Most engines want the oil viscosity to be around 10 cS at normal operating temperature. The really thick multi-grade oils have a viscosity of 20 cS at operating temperature. One is not twice as thick as the other, it is only 10 cS thicker.

As we increase the heat from 212 F to 302 F the most commonly recommended oil

thins from 10 cS to 3 cS. The thicker oil drops from 20 cS to 4 cS. Note that in

a very hot engine the difference between the two oils is now only 1 - 2 cS. In

other words they have about the same thickness. There is little advantage to a

thicker based oil as a 20W-50 at very high temperatures. No, the 4 cS oil is not

twice as thick as the 2 or 3 cS oil. This difference is almost

insignificant.

Using an oil that is less thick at startup has other benefits. Let us compare a

synthetic 10W-30 to a mineral based 10W-30. Both give you a viscosity of 10 cS

at normal engine operating temperatures. They both thin to 3 cS at high

temperatures. At 75 F tomorrow morning the story will be different. The startup

viscosity of the synthetic will be 50 whereas the mineral based 10W-30 will be

100. Again, both are too thick at startup but the synthetic will cause less

startup time period wear and tear. You will get a little better gas mileage

too.

The synthetic lubricated engine will turn over easier. This has the effect of

using less power from your starter motor. It will last longer. Your battery has

less of a current draw. This will also last longer. The battery was discharged

less during the start so the alternator will rob less power from your engine to

recharge. The alternator lasts longer and you get a little better gas economy.

The only downside of synthetic lubricants is the cost. They cost 2 or 3 times as

much as mineral based oils.

Part V

The best way to figure out what viscosity of oil you need is to drive the car in

the conditions you will use. Then use the oil viscosity that gives you 10 PSI

per 1,000 RPM under those circumstances.

These same rules apply to engines of any age, loose or tight. Just because your engine is old does not mean it needs a thicker oil. It will need a thicker oil only if it is overly worn, whether new or old. Yet the same principals of 10 PSI per 1,000 RPM still apply. In all cases you need to try different grade oils and see what happens. Then choose the correct viscosity.

Some people have tried this and occasionally get a somewhat low oil pressure

while at idle. This is fine. There is no stress on parts at idle, the smallest

oil flow will do the trick. It is at higher RPM where stress on the engine is produced. This

is where we need the flow.

Your engine is not producing much heat at low RPM and horsepower outputs. The production of heat is relatively slow. It can easily be transmitted to your cooling system. The problem is that your cooling system has trouble getting rid of the heat. The oil and the coolant will slowly rise in temperature. They both rise together. The increase is no big deal for your oil. It goes to 220, then 230 F. The problem is that the cooling system can only handle heat up to 230 F. After that you overheat the cooling system and the car must be shut off. The oil never got that hot, It was just that the coolant got a little hotter than its system design.

You now see that overheating in traffic is a cooling system problem and not an oil system problem. Do not change to a thicker oil based on your traffic situation.

Part VI

What is the viscosity of the various grade oils? The definitions are as

follows:

From SAE J300, viscosities at 212 F...

Weight and viscosity range:

20, 5.6 to 9.2

30, 9.3 - 12.4

40, 12.5 - 16.2

50, 16.3 - 21.8

60, 21.9 - 26.1

A 20 grade oil is not half as thick as a 40 grade oil. A 40 grade oil is only around 10 percent thicker than the 20 grade oil. The difference is not that much at normal operating temperatures but at startup the difference is significant.

Here is an interesting tidbit of information. A 75W-90 gear oil has the same

viscosity as a 10W-40 engine oil at 212 and 302 F. Once again, those numbers on

that oil can are misleading and certainly add to the confusion we see among

automotive enthusiasts. At 75 F gear oils are much thicker than motor oils.

There are no start up issues so pour point depressants are not added that

minimize the thickening with cooling in gear oils.

Part VII

We have seen that 0W-30, 5W-30, 10W-30 and straight 30 grade oils all have the exact same viscosity at 212 and 302 F. What about startup viscosities? Do 0W-20, 0W-30 , and 0W-40 all have the same viscosity at a 75 F startup. The answer is no. The SAE J300 standard allows for this discrepancy. Here are some examples:

..Viscosity at 75 F startup..

...0W-20.....0W-30.....0W-40

.....40............50...........60

The numbers are not exact but they show clearly that the ”0” represents different startup viscosities. This is unlike the 0W-30, 5W-30, 10W-30 and straight 30 grade oils that all have the exact same viscosity in a hot engine = 10 cS.

I give you the following example to help visualize what is happening with motor

oil. This assumes the oil has no internal resistance. In actuality doubling the

pressure will not double the flow but will be slightly less. And thicker oils

have more resistance than thinner oils for all situations. But simplified we get

the following:

For a 30 grade oil at operating temperature:

RPM....Pressure..Flow

1,000......20 PSI....1

2,000......40 PSI....2

4,000......80 PSI....4

8,000... 160 PSI....8 The maximum flow because of the oil pop off valve at 90 PSI will be 5

For a 30 grade oil at operating temperature

and a higher output oil pump:

RPM....Pressure..Flow

1,000......30 PSI....1.5

2,000......60 PSI....3

4,000....120 PSI....6 The maximum flow because of the oil pop off valve at 90 PSI will be 5

8,000... 240 PSI....12

If we stick with the same grade oil and increase the oil pump output we will increase the pressure and the oil flow too. If we double the oil pump output we will double the pressure and we will double the oil flow (in an ideal system). But we are always limited by the oil relief valve:

RPM....Pressure..Flow

1,000......40 PSI....2

2,000......80 PSI....4

4,000....160 PSI....8 The maximum flow because of the oil pop off valve at 90 PSI will be 5

8,000... 320 PSI....16

Let us compare a 40 grade oil at operating temperature:

The oil is thicker, has more internal resistance and therefore requires more pressure to get the same flow (baseline engine).

RPM....Pressure..Flow

1,000......30 PSI....1

2,000......60 PSI....2

4,000....120 PSI....4 The maximum flow because of the oil pop off valve at 90 PSI will be 3

8,000....240 PSI....8

For a 40 grade oil at operating temperature

and a higher output oil pump:

RPM....Pressure..Flow

1,000......45 PSI....1.5

2,000......90 PSI....3 The maximum flow because of the oil pop off valve at 90 PSI will be 3

4,000....180 PSI....6

8,000... 360 PSI....12

For a 40 grade oil at operating temperature

with the original pressures:

RPM....Pressure..Flow

1,000......20 PSI....0.5

2,000......40 PSI....1

4,000......80 PSI....2

8,000... 160 PSI....4 The maximum flow because of the oil pop off valve at 90 PSI will be 3

Increasing the pressure while using the same oil will increase the oil flow but increasing the pressure by increasing the oil thickness will result in less flow. It takes more pressure to move a thicker oil. When you go to a thicker oil the pressure goes up because of the increased resistance, and therefore reduction of flow. Because the pressure is higher sooner, the relief valve cuts in sooner. Flow will actually be less when the RPM is up and the flow is needed the most.

Part VIII

We are going to bring up the constant flow pump concept. First, it goes back to the principal that doubling the pressure of the same grade oil does not exactly double the flow but it is close. Also doubling the RPM for the same reason does not exactly double the flow but again it is close.

This shows the problem best:

(A) For a 30 grade oil at operating temperature:

RPM....Pressure..Flow

1,000......20 PSI....1

2,000......40 PSI....2

4,000......80 PSI....4

8,000... 160 PSI....8 The maximum flow because of the oil pop off valve at 90 PSI will be 5

(B) For a 30 grade oil at operating temperature

and a higher output oil pump:

RPM....Pressure..Flow

1,000......30 PSI....1.5

2,000......60 PSI....3

4,000....120 PSI....6 The maximum flow because of the oil pop off valve at 90 PSI will be 5

8,000... 240 PSI....12

If we stick with the same grade oil and increase the oil pump output we will increase the pressure and the oil flow too. If we double the oil pump output we will double the pressure and we will double the oil flow.

(C) For a 40 grade oil at operating temperature:

The oil is thicker, has more internal resistance and therefore requires more pressure to get the same flow. Compare this with (A):

RPM....Pressure..Flow

1,000......30 PSI....1

2,000......60 PSI....2

4,000....120 PSI....4 The maximum flow because of the oil pop off valve at 90 PSI will be 3

8,000....240 PSI....8

(D) For a 40 grade oil at operating temperature

and a higher output oil pump:

RPM....Pressure..Flow

1,000......45 PSI....1.5

2,000......90 PSI....3 The maximum flow because of the oil pop off valve at 90 PSI will be 3

4,000....180 PSI....6

8,000... 360 PSI....12

The situations (A) and (C) are close to real life, assuming no loss in the system. This is what happens when you change the 30 grade oil to a 40 grade oil in your car:

(A) For a 30 grade oil at operating temperature:

RPM....Pressure..Flow

1,000......20 PSI....1

2,000......40 PSI....2

4,000......80 PSI....4

8,000... 160 PSI....8 The maximum flow because of the oil pop off valve at 90 PSI will be 5

(C) For a 40 grade oil at operating temperature:

The oil is thicker, has more internal resistance and therefore requires more pressure to get the same flow.

RPM....Pressure..Flow

1,000......30 PSI....1

2,000......60 PSI....2

4,000....120 PSI....4 The maximum flow because of the oil pop off valve at 90 PSI will be 3

8,000....240 PSI....8

At 6,000 RPM the maximum rate of flow has been reached with the thinner oil (A). When you go to 7, 8 or 9,000 RPM you do not get any more flow. You only get a maximum rate of 5. The internal forces on the bearings increase but there is no additional flow of oil.

With the thicker oil you reach maximum flow at 3,000 RPM (C). Worse yet is that the maximum flow is now only 3. As we increase RPM to 4, 5, 6, 7, 8, 9,000 RPM we get no additional pressure and no additional flow, no increase in lubrication.

Next let us look at a 20 grade oil at operating temperature. We get the same flow out of our constant volume pump but the thinner oil requires less pressure to move through the system. This even goes along with the rule that we should use an oil that gives us 10 PSI per 1,000 RPM:

(D) RPM....Pressure..Flow

1,000......10 PSI....1

2,000......20 PSI....2

4,000......40 PSI....4

8,000.. ...80 PSI....8

The maximum flow rate has not been reached. If the engine went to 9,000 RPM then the flow would be 9 at 90 PSI, our maximum pressure at pop off. The engine now has 3 times the flow rate as with the 40 grade oil at full RPM. The nozzles at the bottom of each cylinder are spraying 3 times the amount of oil lubricating and cooling this section. Everything runs cooler and the separation forces in the bearings are 3 times higher.

For engines that redline at 5,000 RPM they usually pop off the oil pressure at 50 to 60 PSI. For engines that go to 8-9,000 RPM the pressures max out at 90-100 PSI. You can now see that you can only get the maximum flow rate if you follow the 10 PSI / 1,000 RPM rule.

Finally we will compare a single, 30 grade oil, at normal (212 F) and at

racetrack (302 F) temperatures:

(A) For a 30 grade oil at normal (212 F) operating temperature:

RPM....Pressure..Flow

1,000......20 PSI....1

2,000......40 PSI....2

4,000......80 PSI....4

8,000... 160 PSI....8 The maximum flow because of the oil pop off valve at 90 PSI will be 5

(E) For a 30 grade oil at elevated (302 F) operating temperature. The oil is thinner at 302 F. It requires less pressure to get the same flow:

RPM....Pressure..Flow

1,000......10 PSI....1

2,000......20 PSI....2

4,000......40 PSI....4

8,000......80 PSI....8 The maximum flow because of the oil pop off valve at 90 PSI will be 9

The hotter (302 F) 30 grade oil is thinner than the cooler (212 F) 30 grade oil. It has the same flow rate in the constant volume oil pump but at a lower pressure than the oil at normal operating temperature. This allows for a doubling of the flow rate at peak RPM. The thinning of oil at higher temperatures is a benefit. You get more flow, more cooling and more lubrication.

The 30 grade oil at 302 F has the exact same flow rate and pressures as the 20 grade oil at 212 F. See (D) above. Therefore, use the 20 grade for around town driving and the 30 grade on the hot track. You get maximum flow at each situation.

For YOUR engine, substitute the actual flow at 1,000 RPM. If your engine puts out 1.5 liters/min. at 1,000 RPM it would put out 3 liters/min. at 2,000 RPM and 6 liters/min. at 4,000 RPM and so on. The maximum flow in (A) would be 7.5 liters/min. In situations (D) and (E) you would get a maximum of 13.5 liters/min.

Conclusions:

The reason that multi-grade oils were developed in the first place was to address the problem of oil thickening after engine shutdown. Over the years we have been able to reduce the amount of thickening that occurs. Never-the-less there is no oil that does not thicken after you turn your engine off. This is why we have to warm up our engines before revving them up. Engine designers always pick the recommended oil based on a hot engine and hot oil. There is no issue with oil thinning as they are both matched when hot. The problem is oil thickening when the engine cools.

Cold engine showing very high pressures because of the thickened oil at startup:

For a 40 grade oil at 75 F at startup:

The oil is thicker, has more internal resistance and therefore requires more pressure to get the same flow.

RPM....Pressure..Flow

1,000......60 PSI....1

2,000....120 PSI....2 The maximum flow because of the oil pop off valve at 90 PSI will be 1.5

4,000....240 PSI....4

8,000....480 PSI....8

At 1,500 RPM you reach the maximum oil flow rate and if you run to 8,000 RPM it is the same rate. The flow cannot increase and it is insufficient. This is why we must wait until our oil temperature comes up to 212 F or higher. The maximum flow rate in this case will then double, up to 3. To get even more flow in our test engine you need to use a lower viscosity grade.

If you have absorbed and digested the information here you should be able to pick out the proper operating oil grade for your car, be it a 30, 40, 50 or even 20 grade oil. I have always used oils that were a grade thinner than recommended even though many use a grade thicker than recommended. I showed evidence that the starting grade should always be 0 or 5 (0W-XX or 5W-XX for thicker oils). If you want the best protection and highest output from your motor use a synthetic based oil.

Read Motor Oil Basics by Dr. Ali E. Haas (AEHaas)

GF-5 Motor Oil

Toyota Motor Oil Chart

Motor Oil Myths according to Valvoline

What Wikipedia Has To Say About Motor Oil

Are Timken Bearing Machine Results Meaningful?

What makes ATF different than motor oil?

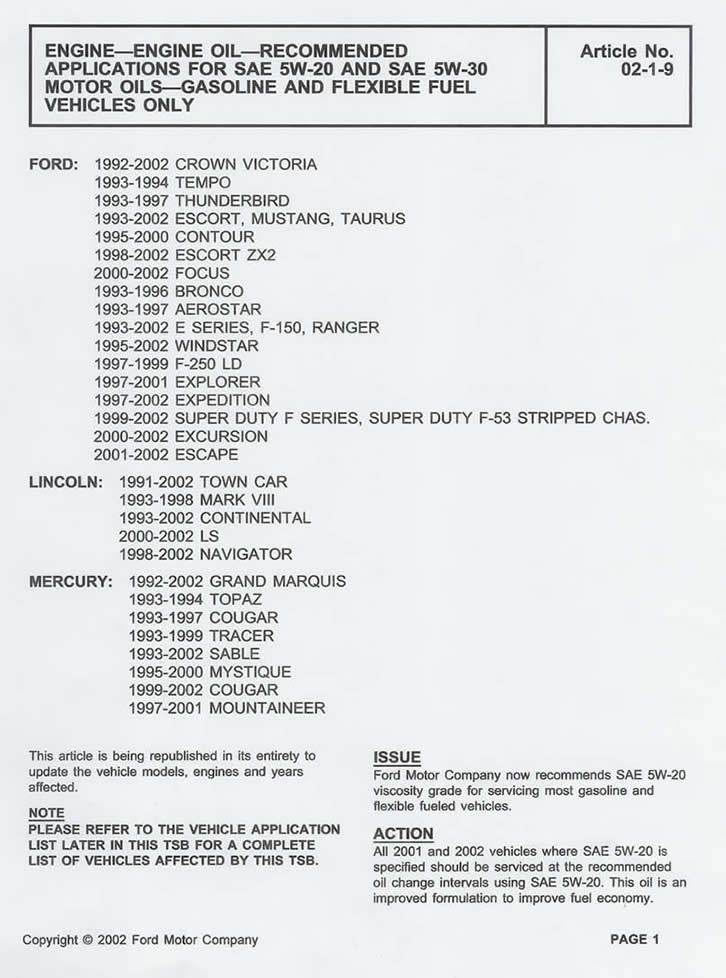

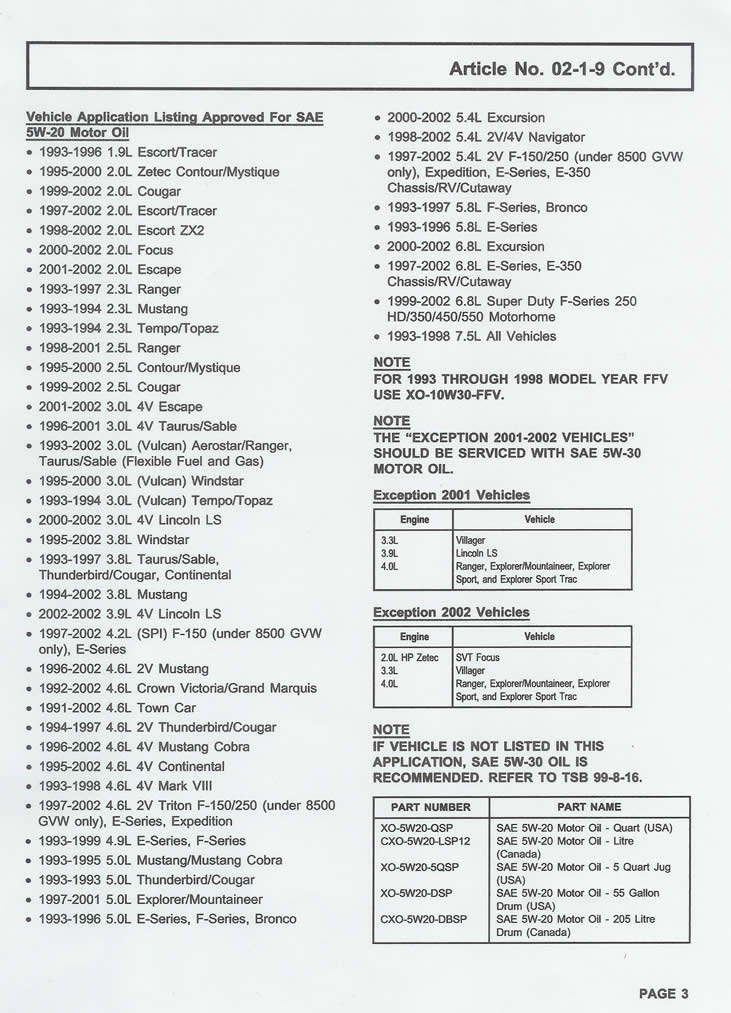

Ford Revised Motorcraft Oil Recommendations:

|